Enquire Now in Rockhampton

Rockhampton Engineering Services

Hardarc Engineering delivers hands-on support to industrial, agricultural, transport and mechanical clients across Rockhampton. From general breakdown repairs to specialised fabrication and machining, we’re equipped to take on both one-off jobs and ongoing work. Our team combines practical experience with technical skill to ensure parts are restored, equipment is modified and problems are solved.

If you need something repaired, machined or made from scratch, we’re ready to help. Call 0409 133 455 to speak with Hardarc Engineering today.

Consistent Quality & Support

We’ve built long-standing relationships in Rockhampton by consistently delivering work that holds up under pressure.

- Experience Across Key Industries – We support rural operators, fabricators, marine trades, workshops and maintenance teams across the region.

- Skilled Trades, One Location – Our team handles turning, welding, fabrication and machining in-house for better turnaround and accuracy.

- Capable of Complex Work – We frequently assist with difficult or unusual tasks other shops aren’t set up for.

- Prompt, No-Fuss Support – We focus on the work, not the runaround—getting your job completed without unnecessary delay.

- Safety-Ready & Fully Licensed – With QBCC licensing and a safety-first mindset, we’re trusted to complete jobs to a professional standard.

Whether you’re stuck mid-repair or planning a project, we offer practical, outcome-focused engineering services across Rockhampton.c

Enquire Now in Rockhampton

Address

Contact

T. 0409 133 455

Opening Hours

Mon-Fri 06:30am - 7:00pm

Sat Appointment Only

Sun Closed

Mechanical Services

We provide mechanical engineering in Rockhampton to solve equipment issues, refine systems, and customise machinery for specific applications.

Damaged or obsolete vehicle parts are repaired in Rockhampton using machining, welding and rebuild methods to extend their usability.

Our automotive fabrication services in Rockhampton include reinforcing vehicle frames, fabricating mounts, and creating custom components for modified or restored vehicles.

We overhaul and repair Machinery in Rockhampton to restore functionality, extend equipment life, and prevent downtime.

Fabrication & Welding

We install and configure production line components in Rockhampton to support new system setups and equipment integration.

Plasma cutting in Rockhampton is used to achieve sharp, clean cuts in steel, stainless and aluminium for both repair and fabrication projects.

We perform specialised welding in Rockhampton for structural, stainless and alloy-based applications that demand strength and precision.

We supply and install screw piles in Rockhampton for structures that need fast, stable, low-disruption foundation support.

Machining Services

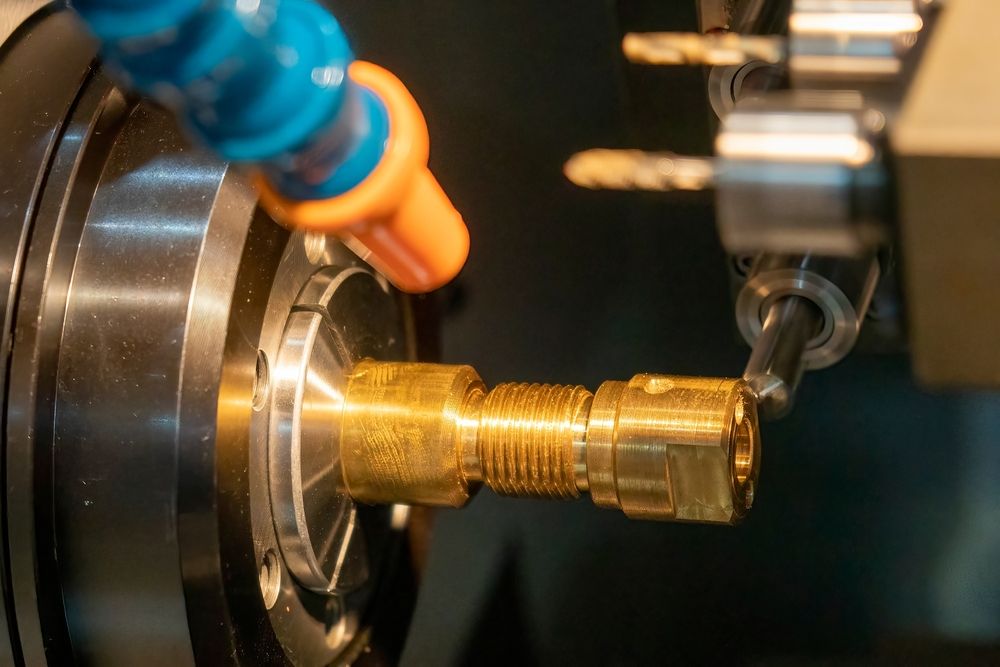

Using precision machining we create accurate parts for mechanical repairs, new assemblies, and performance-critical applications in Rockhampton across multiple industries.

We complete milling, drilling and slotting tasks in Rockhampton to modify components, prepare structural materials, and fabricate new parts with exact dimensions.

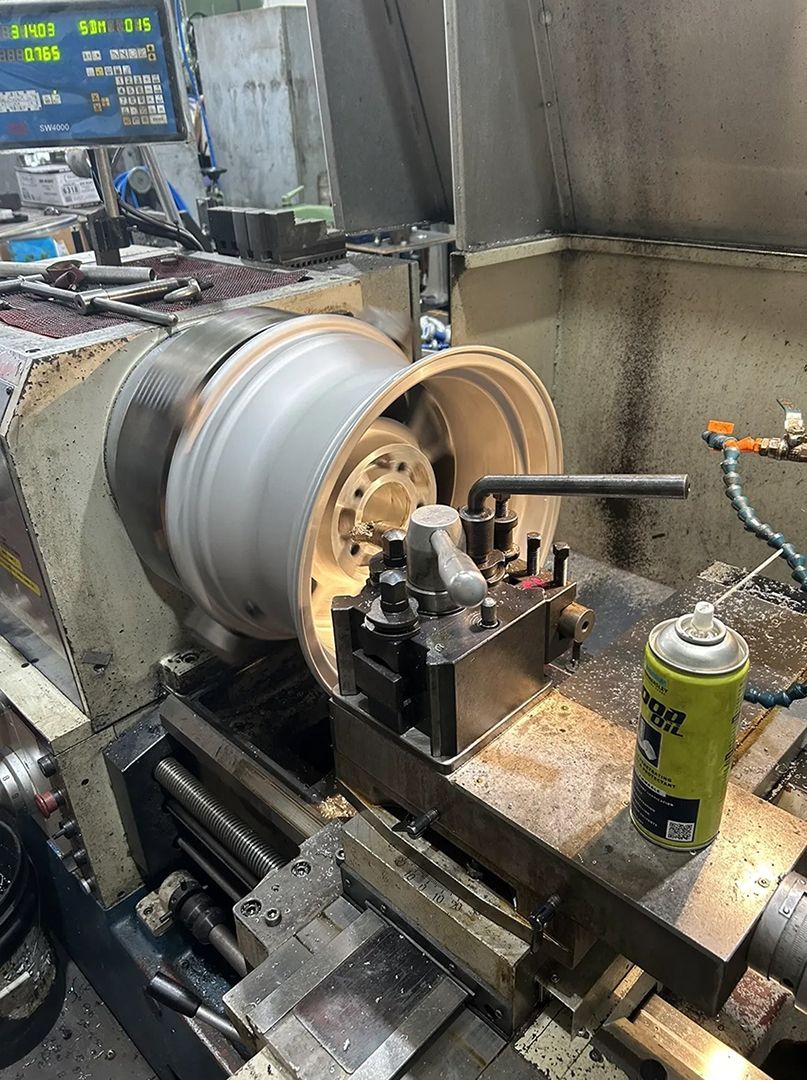

Lathe metal turning enables us to shape cylindrical parts in Rockhampton, like pins and rollers to precise dimensions for mechanical systems.

We offer fitting and turning in Rockhampton for projects that require accurate part installation, reassembly, or alignment in mechanical systems.

In Rockhampton, we use horizontal and vertical boring to drill accurate holes through heavy or complex materials in structural and industrial projects.