Enquire Now in Gympie

Gympie Engineering Services

Hardarc Engineering delivers professional engineering services to clients across Gympie, supporting agriculture, light industrial, manufacturing and machinery sectors. Our team works with everything from worn equipment and vintage vehicles to modern systems and heavy plant. Backed by decades of hands-on experience, we provide practical support for repairs, maintenance and fabrication needs.

Whether you need something built, rebuilt or modified, we’re here to help. Contact Hardarc Engineering today on 0409 133 455 to get started.

Why Customers Trust Us

Locals rely on Hardarc Engineering for more than just quality workmanship—they come to us for insight, adaptability and results.

- Long-Term Industry Knowledge – We’ve been in the trade for decades, giving us the insight to solve technical and site-based challenges.

- Workshop & Field Capability – Equipped for both in-house and on-site jobs, including mobile welding, fabrication and mechanical repair work.

- Unusual Projects Welcomed – We regularly assist with custom parts, retrofitted components, and jobs that require creative thinking.

- Fast Turnarounds Where It Counts – We understand operational downtime and aim to complete most work as efficiently as possible.

- Licenced & Insured – Hardarc is fully QBCC licenced and carries appropriate insurances to meet contractor and client requirements.

From local machinery operators to commercial clients, our team continues to support the Gympie region with reliable, specialised engineering services.

Enquire Now in Gympie

Address

Contact

T. 0409 133 455

Opening Hours

Mon-Fri 06:30am - 7:00pm

Sat Appointment Only

Sun Closed

Mechanical Services

We support clients in Gympie with mechanical engineering services such as redesigns, component analysis, and structural improvement work.

We repair automotive components in Gympie, helping restore older or rare parts with machining and fabrication techniques.

Our automotive fabrication work in Gympie includes structural modifications, part rebuilding and bracket or mount fabrication.

Gympie clients trust us with machinery repairs that prioritise functionality, safety and operational continuity.

Fabrication & Welding

We assist with production line installations in Gympie, from fitting support structures to configuring equipment and mechanical systems.

Our plasma cutting services in Gympie produce clean, accurate results for structural and component-related work.

We provide advanced welding in Gympie for stainless, alloy and carbon steel parts requiring strong, clean joins.

Our team supplies and installs screw piles in Gympie for sheds, retaining walls and structural foundations.

Machining Services

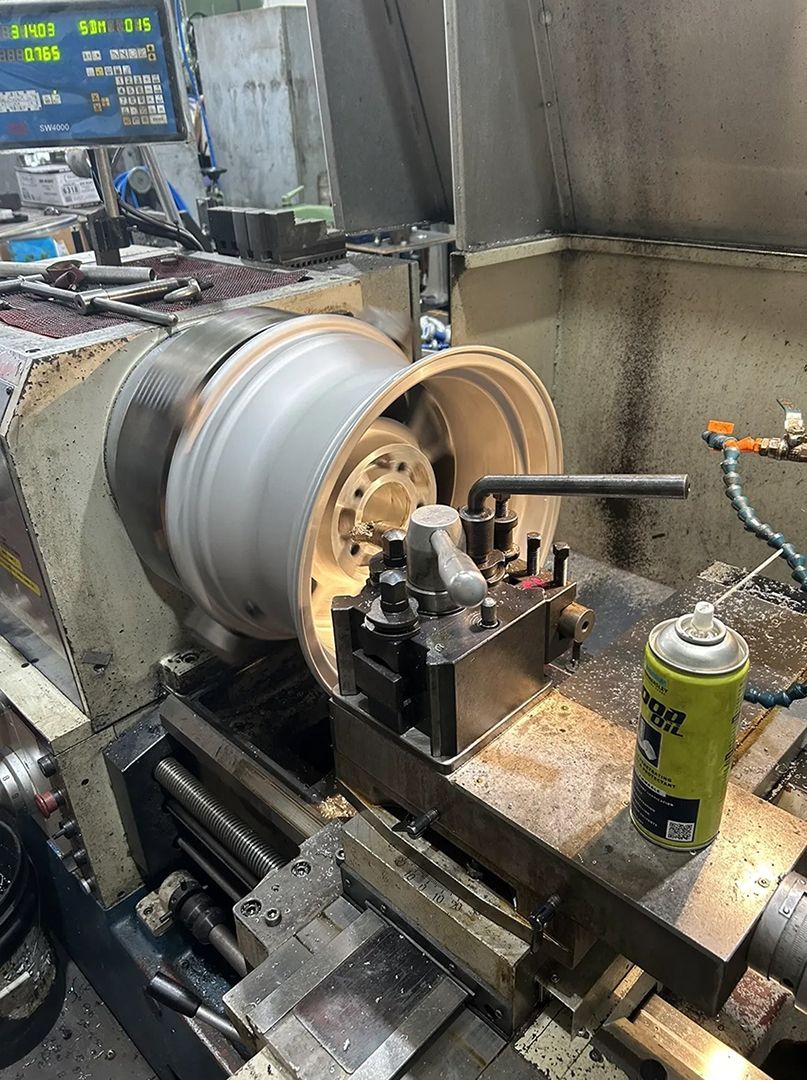

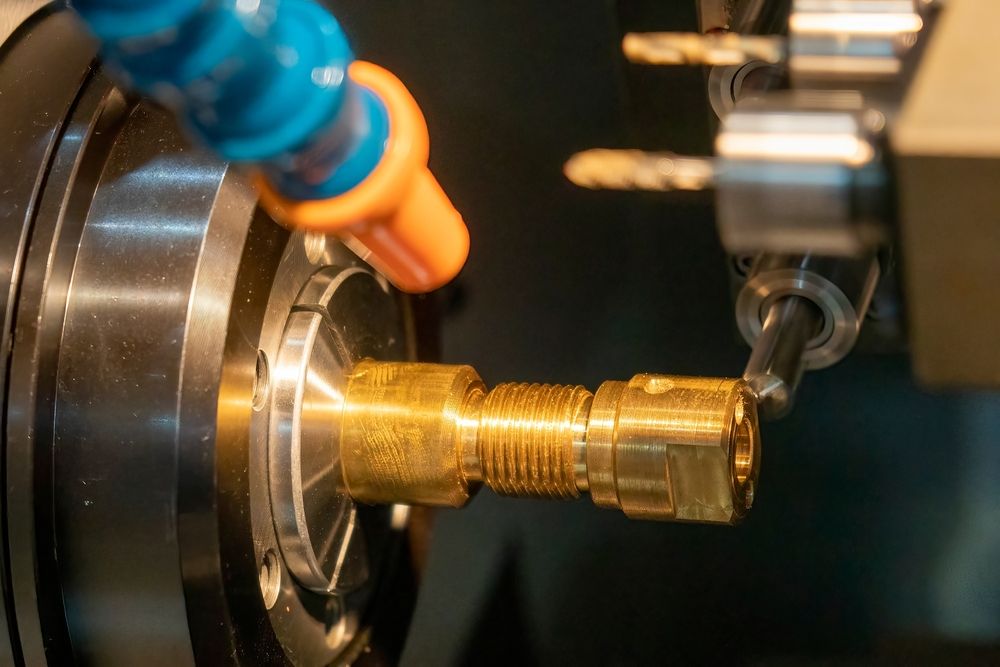

We offer precision machining services in Gympie, delivering tight-tolerance results for a wide variety of part sizes and materials.

Our Gympie machining team handles detailed milling, drilling and slotting work for custom or replacement parts.

Lathe metal turning in Gympie is ideal for shafts, spacers, rollers and other round metal components.

Our team provides fitting and turning services in Gympie for part refurbishments and new component installations.

We operate horizontal and vertical borers in Gympie to achieve precise holes in thick or complex materials.