Enquire Now in Bundaberg

Bundaberg Engineering Services

Hardarc Engineering delivers expert engineering services to clients across Bundaberg, working with operators in agriculture, processing, marine, transport and mechanical industries. We take on jobs other workshops avoid, including high-tolerance machining, custom metalwork and equipment rebuilds.

With decades of industry experience, our team provides practical support for fabrication, installation and complex repairs. Whether you need a replacement part or a full fabrication job, we can help. Call 0409 133 455 to speak with Hardarc Engineering today.

Engineering Specialists You Can Trust

Bundaberg clients value our ability to deliver quality outcomes with minimal disruption. Here’s what sets Hardarc Engineering apart:

- Diverse Project Capabilities – From food-grade systems to rural equipment, we tackle a wide range of engineering challenges.

- One Workshop, Many Services – We combine machining, welding and fabrication in-house for more efficient turnaround times.

- Problem Solvers at Heart – We’re known for taking on difficult jobs that require custom solutions or tailored components.

- Flexible to Your Needs – Whether you need mobile work, pickup support or on-site installation, we adapt to the job.

- Fully Licensed & Insured – Our workshop meets industry standards for safety and compliance, including QBCC accreditation.

We continue to support Bundaberg’s operators with engineering services designed for real-world applications.

Enquire Now in Bundaberg

Address

Contact

T. 0409 133 455

Opening Hours

Mon-Fri 06:30am - 7:00pm

Sat Appointment Only

Sun Closed

Mechanical Services

Our mechanical engineering services in Bundaberg include assessment, redesign and improvement of mechanical systems to enhance efficiency and operational reliability.

We handle automotive part repairs in Bundaberg, restoring damaged or worn components to extend their lifespan and ensure continued use.

Automotive fabrication in Bundaberg involves creating custom components, reinforcing structural parts and adjusting vehicle frameworks to meet specific performance or restoration needs.

We perform machinery repairs in Bundaberg for clients needing urgent fixes or long-term maintenance on industrial and agricultural equipment.

Fabrication & Welding

Installation support for production lines in Bundaberg covers equipment positioning, framework setup and system configuration for smooth, safe operation.

Plasma cutting is carried out in Bundaberg to achieve fast, clean cuts through mild or stainless steel for fabrication and repair projects.

We carry out specialised welding in Bundaberg, including TIG and MIG services for jobs requiring precision and strength in various materials.

We provide screw pile supply and installation in Bundaberg for structural applications in construction, civil and industrial projects.

Machining Services

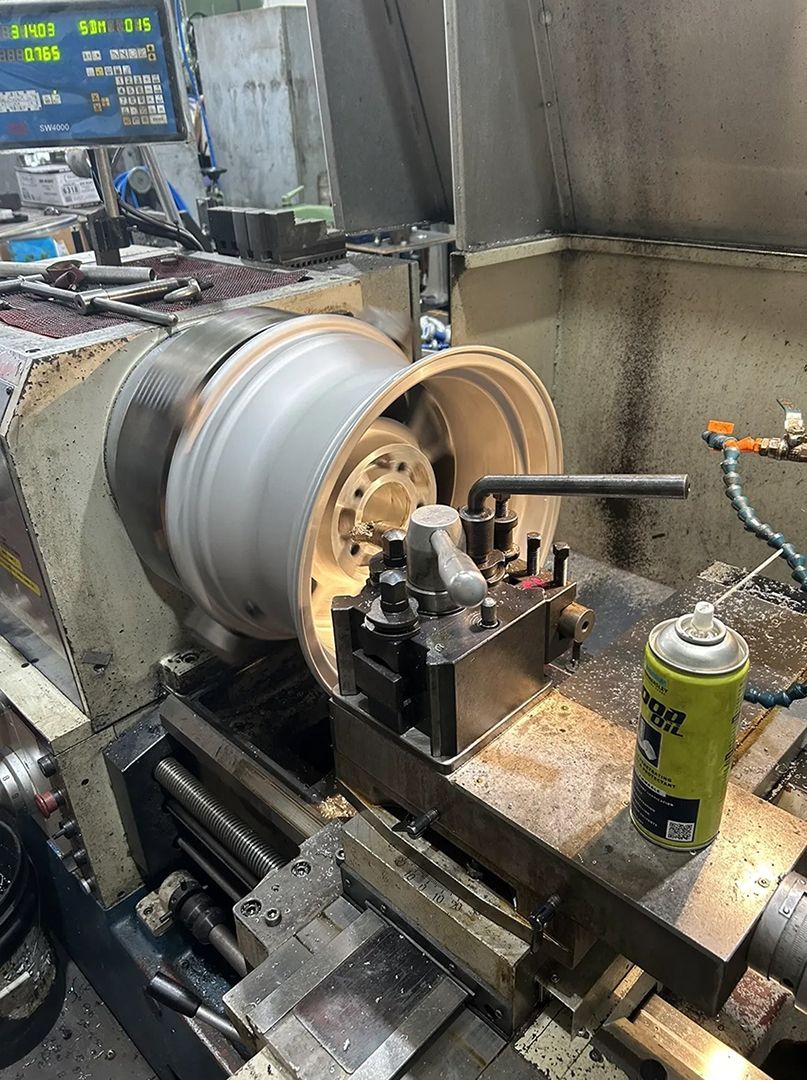

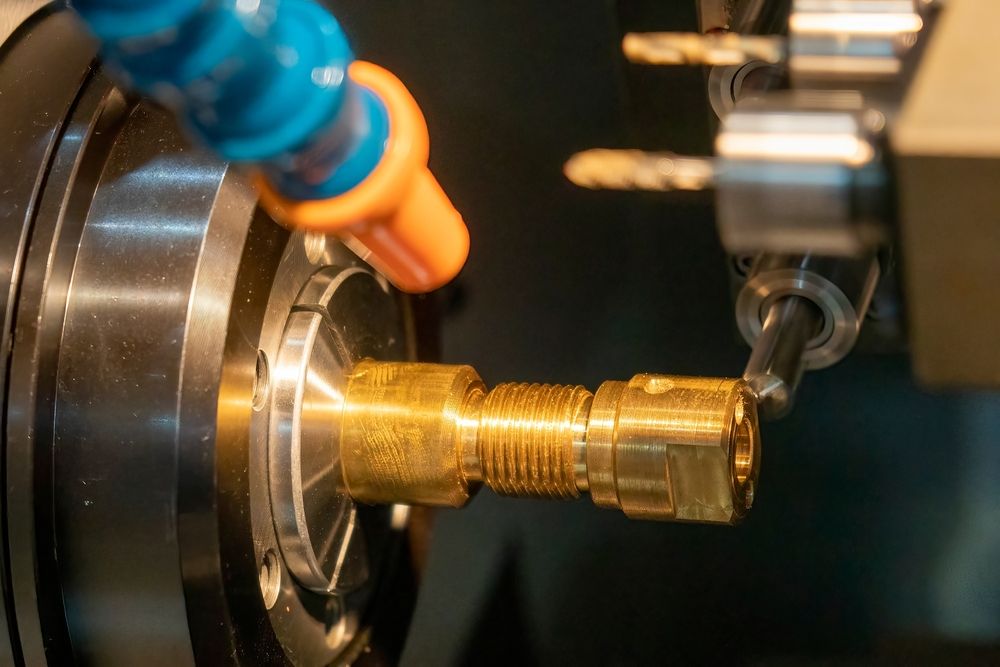

Precision machining in Bundaberg allows for the accurate production of components that meet exact tolerances for equipment assemblies and mechanical rebuilds.

We perform milling, drilling and slotting in Bundaberg to meet design specifications for repair work, equipment upgrades and part fabrication.

Lathe metal turning work in Bundaberg is used to shape cylindrical components like shafts and rollers for manufacturing and repair purposes.

We deliver fitting and turning services in Bundaberg to support equipment builds, refurbishments and precision adjustments for assemblies.

Horizontal and vertical boring services in Bundaberg ensure accurate hole placement through thick materials in structural and mechanical applications.