Enquire Now in Gladstone

Gladstone Engineering Services

Hardarc Engineering supports clients across Gladstone with practical engineering services tailored to the region’s industrial, commercial and marine sectors. From detailed machining to heavy-duty welding, our workshop handles the work others avoid—fast turnarounds, unusual parts, or complex metal fabrication.

Whether you’re modifying existing systems or building from scratch, we provide the tools, skills and experience to get the job done. Call Hardarc Engineering on 0409 133 455 to start your next project today.

Engineering Backed by Quality Service

Clients continue to rely on Hardarc Engineering for our technical ability, broad experience and adaptable support.

- Industry-Spanning Service – We work with marine, mining, construction, food production and plant maintenance clients across the Gladstone region.

- Efficient Turnaround Options – Our in-house capabilities allow us to avoid outsourcing, reducing lead times and transport delays.

- Tailored Solutions Every Time – Whether it’s a prototype part, reworking an existing design, or modifying worn equipment—we work to your specifications.

- Built for Versatility – Our team can move between welding, machining and fitting tasks to meet a wide range of operational needs.

- QBCC Licensed & Workshop-Ready – We meet all licensing and safety standards required for commercial projects and complex mechanical tasks.

We bring practical, dependable engineering services to Gladstone, built around what your operation actually needs.

Enquire Now in Gladstone

Address

Contact

T. 0409 133 455

Opening Hours

Mon-Fri 06:30am - 7:00pm

Sat Appointment Only

Sun Closed

Mechanical Services

We provide mechanical engineering in Gladstone to diagnose faults, improve system performance, and modify machinery to suit specific operational needs.

Using machining and welding techniques, we repair automotive components in Gladstone to bring worn, cracked, or broken parts back to working condition.

Custom frames, structural modifications, and tailored components are fabricated in our Gladstone workshop to meet performance or restoration requirements.

When machinery breaks down in Gladstone, we step in to identify the issue, carry out repairs, and get operations back on track quickly.

Fabrication & Welding

We assist with production line installations in Gladstone by fitting, aligning, and securing equipment to ensure efficient setup and safe operation.

For clean, accurate metal cuts, we use plasma cutting in Gladstone to support fabrication, part replacements, and custom builds.

We offer specialised welding services in Gladstone for stainless steel, alloy, and structural components that require high-strength, clean welds.

We supply and install screw piles in Gladstone for residential, commercial, and industrial projects needing stable, low-impact foundations.

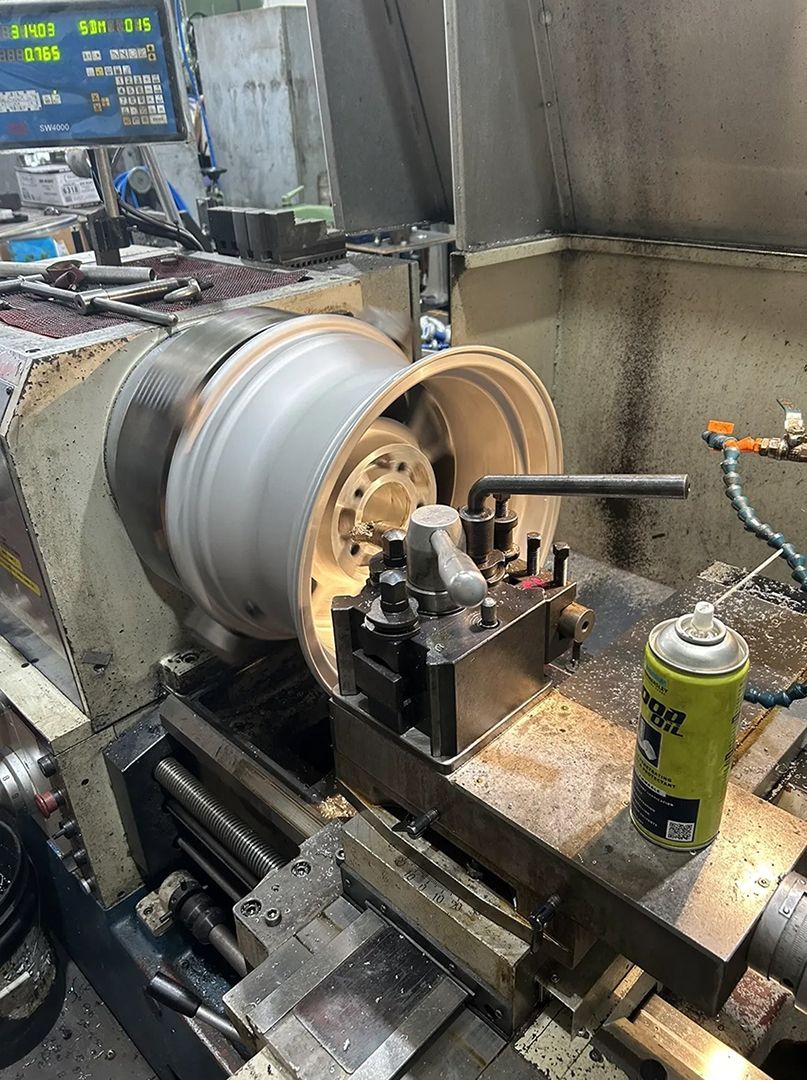

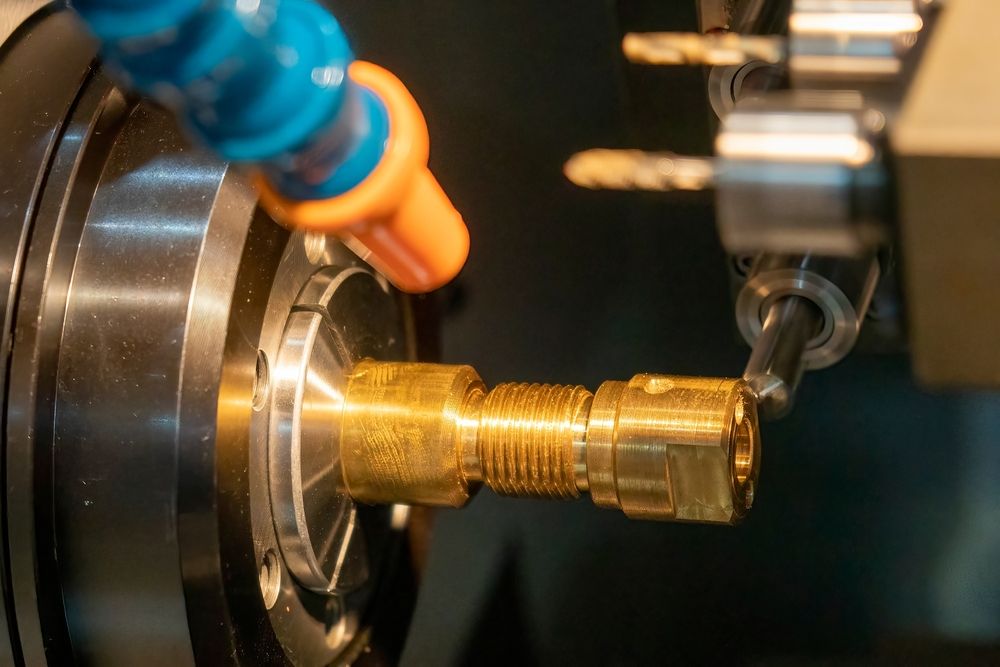

Machining Services

High-tolerance components are produced in Gladstone using precision machining techniques suited to mechanical repairs, upgrades, and new builds.

We carry out milling, drilling, and slotting in Gladstone to create accurate profiles, holes, and adjustments across a wide range of materials.

Lathe metal turning in Gladstone allows us to produce shafts, pins, and other cylindrical parts with smooth finishes and tight tolerances.

We complete fitting and turning in Gladstone to support part assemblies, mechanical installations, and adjustments to existing equipment.

Horizontal and vertical boring is used in Gladstone to place precise, large-diameter holes through structural components and heavy equipment.