Enquire Now in Hervey Bay

Hervey Bay Engineering Services

Hardarc Engineering offers practical engineering solutions across Hervey Bay, supporting trades, industry and agriculture. From machining broken components to fabricating custom frames and restoring rare automotive parts, our team handles jobs other workshops won’t touch.

We work with metals and mechanical systems of all sizes, backed by decades of technical experience. Whether you're tackling a breakdown or planning a build, Hardarc Engineering is ready to assist. Call 0409 133 455 to speak with the team today.

Practical, Local Support

Hervey Bay clients choose Hardarc Engineering for our skill, experience and ability to solve problems others can't.

- Broad Industry Capability – We service a wide range of sectors, including marine, food processing, rural and mechanical applications.

- Skilled Across Disciplines – Our team combines mechanical engineering, machining, welding and fitting under one roof.

- No-Nonsense Workmanship – We focus on getting the job done right, with a practical mindset and attention to detail.

- Responsive to Client Needs – Whether it’s a one-off task or recurring work, we adapt to meet specific job requirements.

- Safety & Compliance Ready – Fully licenced, insured and equipped to meet commercial site entry and safety standards.

Our team is proud to support local operations throughout Hervey Bay with professional services built on skill, reliability and trust.

Enquire Now in Hervey Bay

Address

Contact

T. 0409 133 455

Opening Hours

Mon-Fri 06:30am - 7:00pm

Sat Appointment Only

Sun Closed

Mechanical Services

Hardarc Engineering provides mechanical engineering services in Hervey Bay for plant modifications, system troubleshooting and detailed mechanical assessments.

Automotive part repairs in Hervey Bay cover machining, welding and rebuilds for both common and difficult-to-source components.

Automotive fabrication services in Hervey Bay include structural repairs, component upgrades and custom fit-outs for modified vehicles.

Machinery repairs in Hervey Bay focus on getting critical equipment back online quickly, without compromising performance or durability.

Fabrication & Welding

We help set up and install production lines in Hervey Bay, supporting manufacturers with frame placement, equipment fitting and adjustments.

Our plasma cutting services in Hervey Bay offer sharp, clean results for new fabrications, replacements and custom builds.

Hervey Bay-based welding support includes TIG, MIG and alloy welding for complex or high-strength applications.

Screw pile installation in Hervey Bay provides a dependable base for decks, foundations, retaining walls and structural frames.

Machining Services

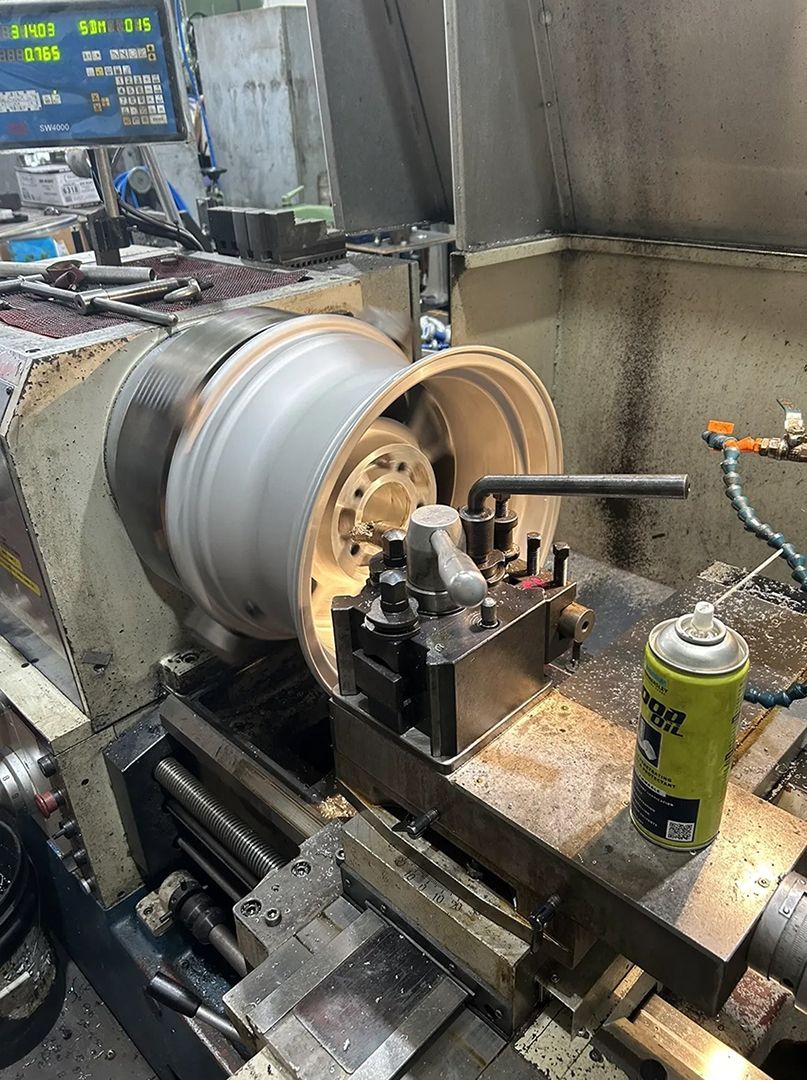

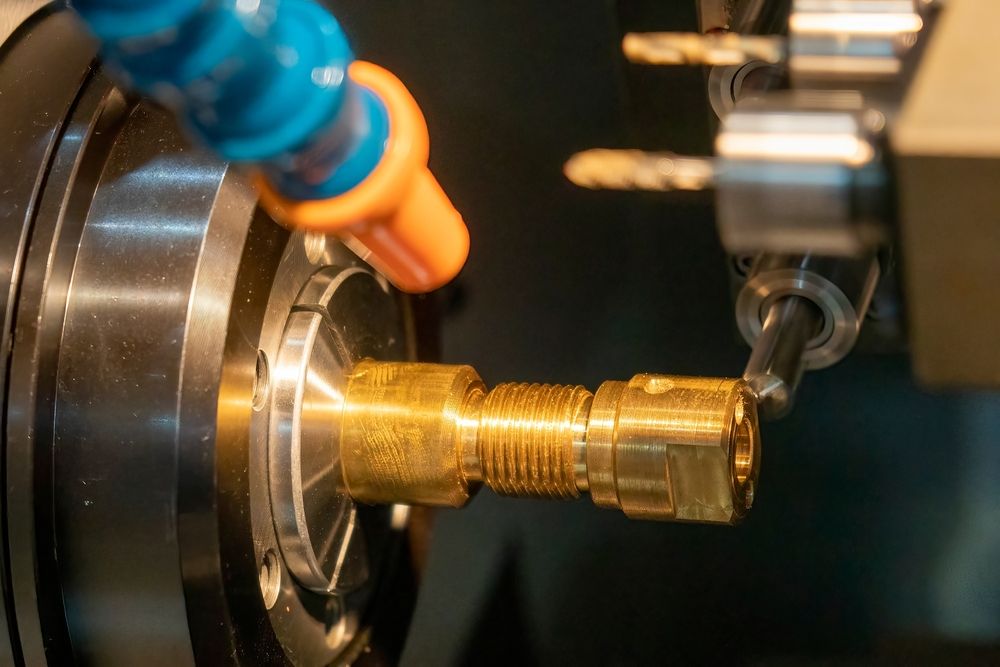

We offer precision machining in Hervey Bay, enabling exact part reproduction for shafts, gears, rollers and more.

We handle milling, drilling and slotting in Hervey Bay for structural elements and custom mechanical parts.

Our lathe turning services in Hervey Bay are ideal for fabricating or modifying cylindrical components such as pins, rods and axles.

Our fitting and turning services in Hervey Bay support installations, part replacements and project-specific assemblies.

We offer boring services in Hervey Bay, including horizontal and vertical setups for deep, accurate hole placement in heavy-duty materials.